Machinery Park

Our Machinery Park – Clarpac’s Heart of Precision & Innovation

We operate a technically advanced and versatile machinery park capable of meeting even the most demanding production requirements.

Where modern technology meets reliability, our facility produces packaging that shapes everyday life. More than just equipment, our machinery park is the driving force behind the consistent delivery of high-quality packaging for the medical, food and pharmaceutical industries.

injection molding machines

blow molding machines

PE injection blow molding machines

PET injection blow molding machines

preform blow molding machines

automation machines

Automation That Gives Us an Edge

Our fully automated machinery park—equipped with 8 modern assembly machines—ensures efficiency, precision and repeatability. Operating across three shifts, five days a week, we’re always ready to meet diverse production needs with flexibility and speed.

Injection Molding Machines

With a fleet of 22 injection molding machines (clamping force 50–220 kN), we deliver reliable production of technical components and packaging. Advanced automation—robots, pickers, volumetric and gravimetric color feeders, grinders and thermostats—ensures precision in every detail.

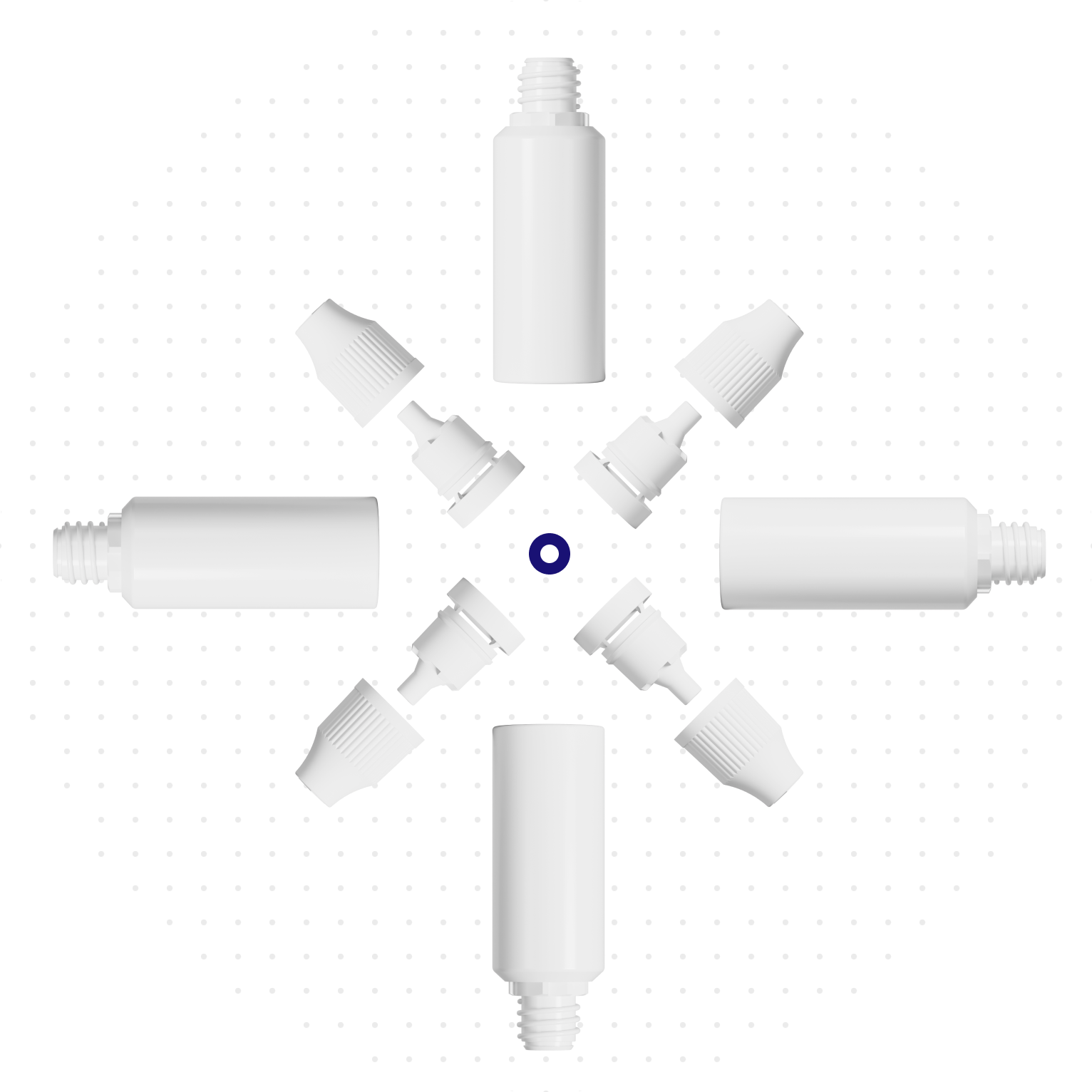

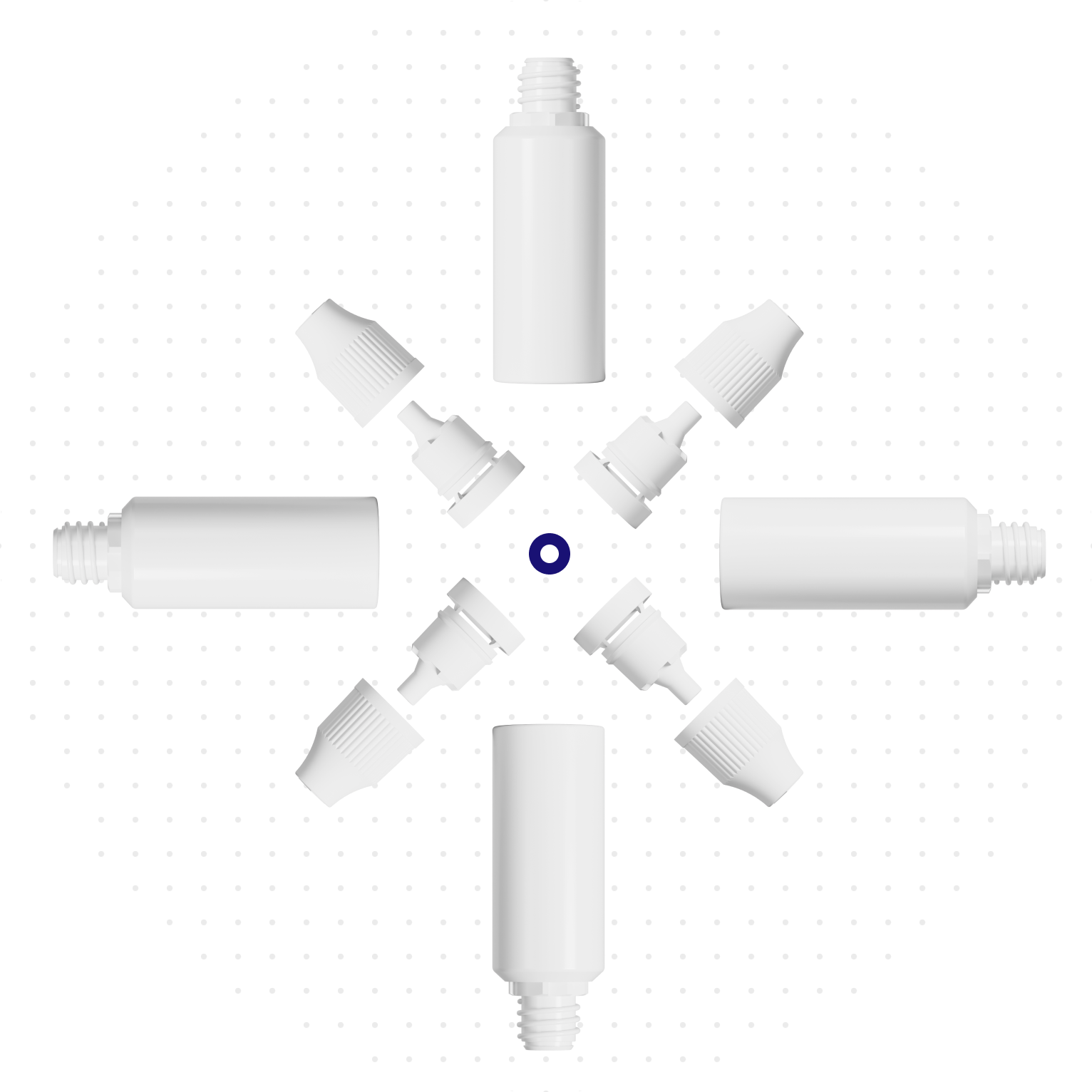

Blow Molding & Injection Blow Molding

We operate 3 injection-blow machines and 4 blow molding machines (including 2 Nissei models), enabling the production of PET packaging ranging from 10 ml to 600 ml. These solutions are ideal for industries where quality, lightness, durability and aesthetics are key.

Pharmaceutical Bottle-Making Machines

Our 12 specialized machines produce bottles from 10 ml up to 1 liter, designed to meet the exacting standards of the pharmaceutical industry.

Quality—Not Just a Promise, but a Standard

We integrate quality control into every stage of production. Continuous monitoring with precision tools (calipers, height gauges, force meters, leak chambers, gauges, induction welders) ensures compliance with the highest standards—confirmed by our ISO 9001:2015 certification and medical device production compliance.

In-House Tool Shop – Know-how Under Control

We design and manufacture our own injection molds in-house. Our tooling department, staffed by experienced specialists, features milling machines, grinders, band saws, microscopes and is supported by Siemens NX and Solid Edge software. We handle full-cycle mold development, modifications, inspections and service—including for hot-runner systems.

Uninterrupted Maintenance

Our dedicated maintenance team ensures production continuity through regular inspections, repair services, automation development and even custom robot construction—keeping us in full control at every production stage.

Reliable Logistics

A structured logistics system based on racking and FIFO (First-In, First-Out) guarantees full traceability of both components and finished products. Each batch is delivered on time with clear identification. By partnering with trusted logistics providers, we ensure seamless coordination from production through to delivery.

People – Our Greatest Asset

Behind every machine is a skilled team. We invest in our people through ongoing training, certifications and a supportive work culture—complete with “Fruit Tuesdays,” team-building events and development programs. It’s our team’s commitment that turns every package into a product we’re proud of.

Business Benefits

- Economies of Scale – Cost efficiency in large-volume production through minimized waste and just-in-time manufacturing cycles.

- Production Flexibility – Rapid adjustment of parameters (pressure, temperature, cooling time) enables quick prototyping and fast implementation of design changes.

- High Quality Assurance – ISO 9001-certified processes and Statistical Process Control (SPC) ensure strict adherence to tolerances and regulatory standards.